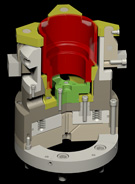

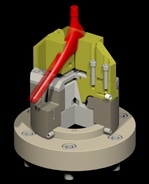

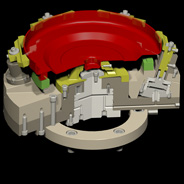

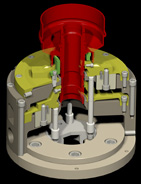

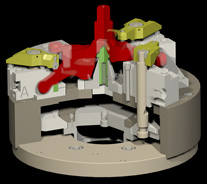

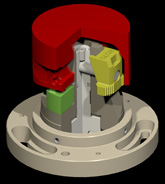

Custom chucks for rough turning, finish turning or grinding applications. Over 50 years of engineering experience goes into every design.

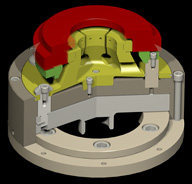

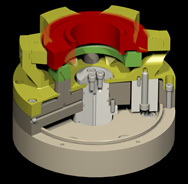

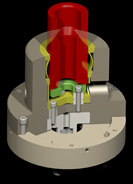

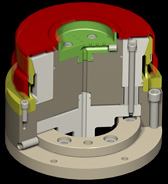

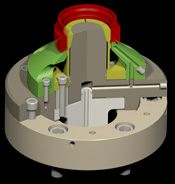

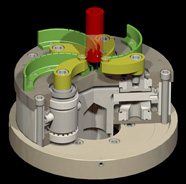

- Clamping Function-Actuation may be hydraulic, pneumatic, manual, internal springs or any combination of these functions.

- High-Precision Designs-Concentricity and repeatability as close as 0.00005.

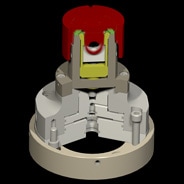

- Pull Back Designs-As the chuck clamps, the part is positively located (pulled back) against the part stop to assure proper part loading.

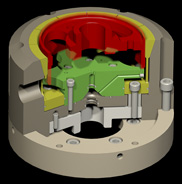

- Static Clamping-Non-Pull Back Chucks. As the chuck clamps, the part piece location is not influenced. Typically utilized for thin wall or thru-hole applications.

- Compensating Designs-The Chuck will compensate as it clamps to allow the part to be radially located prior to clamping. Typically, a gear nest, diamond pin, or center is used to provide location of the part and the chuck clamps the part securely without influencing the part location.

- Thru-Hole Designs-Designs intended to accommodate the use of bar stock. Thru-hole capacity is only limited by the capacity of the machine tool. We can accommodate as large a diameter as required.

- Air Sensing-Proper part location is assured through the use of air sensing through the part stop. Small air passages are routed through the chuck. When the part is clamped properly, the air passages do not allow air to flow through. The machine control senses the presence or lack of air flow, assuring proper part location.

- Counter Centrifugal Designs-Our chucks are precision balanced to accommodate high RPM applications. Thus, the effects of centrifugal force are negated.