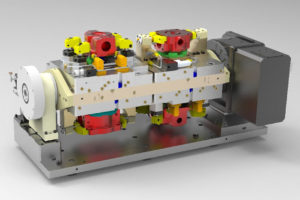

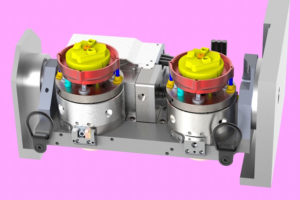

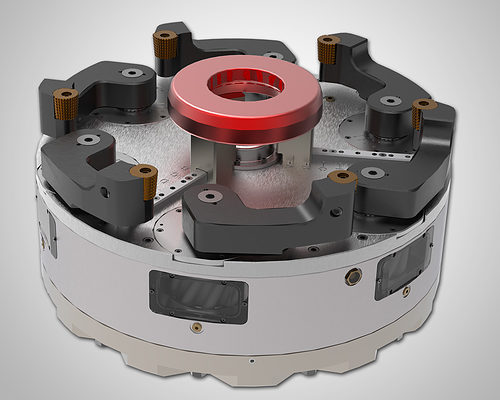

Eliminate Top Tooling Changeover

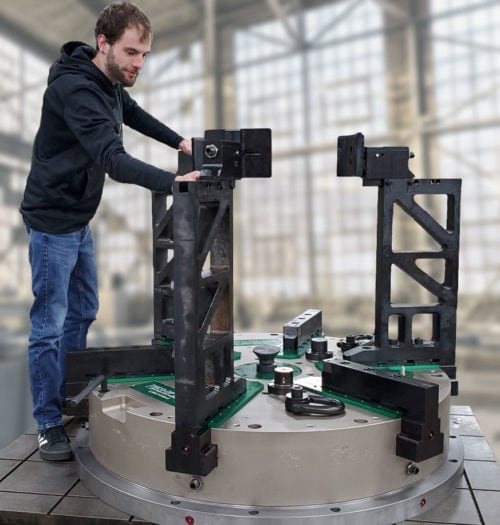

This gear supplier reduced change-over time from hours to minutes!

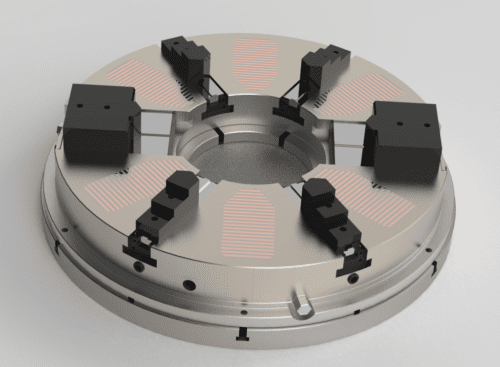

Our patented Iris Chuck ™ grips a HUGE range of parts with fast and easy clamp arm adjustments. Far greater grip range than any sliding jaw chuck and without changing out jaws. You can even grip parts larger than the chuck O.D. Changing from I.D to O.D. gripping is as easy as rotating the clamp arms 180 degrees.